The Toy Village Seiffen in the changing seasons

Seiffen – where does its name come from?

As long as about 750 years ago, the densely-growing vegetation (Miriquidi) of the Erzgebirge Mountains was hard to pass through. There were only a few tracks known as salt roads on which, as the name says, salt was transported from the area of today’s Halle to Bohemia. This changed when rich deposits of silver were found close to Freiberg. People supposed there were more riches to be discovered further up the hills. The news spread quickly as far as Bohemia.

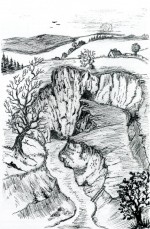

In those days, Cistercian monks lived in the monastery of Ossegg. They dedicated themselves to God. They promised to neglect any personal wealth and to be obedient to both God and their superiors. Pray and work – that was their credo. Several times a day, they met for services and prayers, in between which they were busy working the monastery’s fields, building structures or developing new technologies. They were best known for their skills in mining and making glass. The monks had received property from the knights of Riesenburg, who ruled the region. Consequently, the knights urged the monks to look for ores in parts of the Erzgebirge Mountains accessible to them. Ores are metals contained in rock. Still today, the ruin of Riesenburg Castle can be seen on top of a wooded hill. It was a large building. Climbing the steep southern slopes of the Erzgebirge, the monks set out to explore the brooks in the mountains. They knew some of the minerals available in the rocks would be found in the sand.

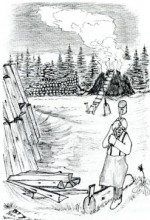

Here in the area of Seiffen, they did find something: Those small greyish gravels they saw contained tin! In the Middle Ages, tin was of high importance. A wide range of articles were made of it, among them plates, cups and even organ pipes. Mixing tin and copper in a 1:4 proportion, people were able to make highly valuable brass, which was needed to produce bells and many other things. The monks started to cut trees and dig trenches into the slopes. The stone rubble containing tin was thrown into the trenches. The trenches were then flooded, the water running into deep holes further downhill. These holes became known as Zinnseiffen (places of washing tin). The gravel contain-ing tin sank to the ground of the holes from where it could be transported to places of further processing. This kind of hard work is where our village has its name from. The village was first mentioned in a document in 1324. Tin was found here for a couple of centuries. The technology decribed above was used as long as about 1700. Erecting Zinnseiffen and other mining plants meant much wood needed to be cut down. Of course, the wood was used to build houses and huts. To an even larger degree, wood was made into charcoal or burnt in the glassmills of the region.

How did the place of mining turn into a toy-producing village?

For long, the people of Seiffen lived on mining. They mined the tin the way the Cistercian monks knew. The metal found was quite pure so it could easily be melted into a product ready for the market. Quantities, however, were small so later on, the metal was also mined from hard rock. Tunnels were driven into the rock. Extensive and deep holes (regional German: Binge, say: binga) were dug into the ground. In a number of places, such holes resulted from mining tunnels collapsing. Visitors may see one of them here in Seiffen. We suppose this Binge is what remains from open-cast mining (a technology known from quarries). To produce a ton of tin, some two hundred cubic metres of overburden had to be excavated and transported. The metal found was taken to stamp-mills where a water-driven wheel moved large rams of wood, which hammered on the ore so it broke. Tin melts at only 232 centigrade. To achieve this temperature, charcoal was burned. Then, a number of finishing processes followed so the metal acquired its final quality, ready to be made into a large variety of products. Miners were paid very low wages, no more than one taler (pronunciation: “a” like in “father”) a week, which their families could hardly live on.

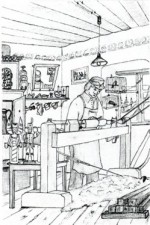

Mining flourished around 1730. About 25 tons of tin were produced in Seiffen and the neighbouring village of Heidelberg. The most productive mines were Rote Grube (one and a half tons), Geyerin (three tons) and Binge (two and a half tons). In Heidelberg, four and a half tons were foundd at Untere Kieszeche (lower gravel mine), ten tons at Obere Kieszeche (upper gravel mine). At Erzengel Michael (Archangel Michael Mine), two and a quarter of a ton were produced. However, it was frequent that little ore was found so little money was earned. Happily in such situations, there was another field of business in Seiffen to make a living on: glass-blowing. Here in the Erzgebirge Mountains, quartz was melted (wood was burned). The glass was further processed. There were a number of glass-making mills in Seiffen and the environs, the one in Heidelbach at the foot of Schwartenberg Hill being the most important one. The patterns needed were turned from wood. This is what we call wood-turning: A piece of wood is driven onto the shaft of a turning bench. Via a belt, the shaft is put to rotation, the turner operating a foot pedal. In othercases, the rotation results from water power. Then, the turner applies a turning knife tostrip off the wood as much as the thing he wants to make requires. Anything can be made this way, there are no limits to fantasy.

Soon people found out that the technology of wood-turning was not only helpful to make the patterns to produce articles of glass. It could as well be used to make plates and bowls and cups. No later than the end of the 17th century, a Seiffen trader by the name of Hiemann pushed his wheel-barrow as far as 130 kilometres to reach the Leipzig Fair where he sold his goods. Then, people realized that also toys could be made this way. To this end, wheel-turning was introduced. A ring of wood is turned on a turning bench. The cross-section of the ring shows the profile of the animal wanted. Then, the ring is cut to portions so very quickly, one gets a certain number of equally-looking animals which afterwards are finished by means of carving. Finally, the articles are painted. This way, production is time-saving and articles can be sold at a lower price.

Around 1850, mining came to a stop here. Step by step, Seiffen became known as a toy-making village and won its fame as a place where articles for Christmas are made. Many companies, smaller or larger, make wonder-ful pyramids, candlesticks, angels, miners or nutcrackers, all of wood. In some of the workshops visitors can even watch the turners or painters at work.